"FLOREASY INDIA PVT LTD"

Your Coir Companion for Green Living

“FLOREASY INDIA PVT LTD “is your trusted partner in embracing a greener and more sustainable way of living. Our eco-friendly coir products are designed to make a positive impact on the environment while enhancing the quality of your life. With a wide range of coir-based solutions, we cater to various needs, from organic gardening and landscaping to erosion control and industrial applications. Our commitment to quality and sustainability is at the core of everything we do, ensuring that you receive products that not only meet the highest standards but also support a healthier planet. Join us in your journey towards green living by choosing FLOREASY INDIA (P) Ltd. Experience the natural, renewable, and biodegradable qualities of coir, and be a part of the solution for a more sustainable future. Let our coir products be your reliable companion in your quest for a greener, more eco-conscious lifestyle. “This paragraph elaborates on the heading, emphasizing the company’s focus on eco-friendly living and the versatility of their coir products for various applications. It also encourages the reader to join in the sustainable living journey with FLOREASY INDIA (P) Ltd.

Gardeners know that the secret ingredient to flowering success is the cocopeat

INNOVATIVE PRODUCTS

COCOPEAT

Dry

sieved cocopeat directly sourced from Factory

Cocopeat is a natural fibre made out of coconut husks. The extraction of the coconut fibre from husks gives us this by-product called cocopeat.

WOODFIBER

Wood Fibre are usually cellulosic elements that are extracted from trees. The Wood fibre is extracted from Spruce trees in FRANCE.

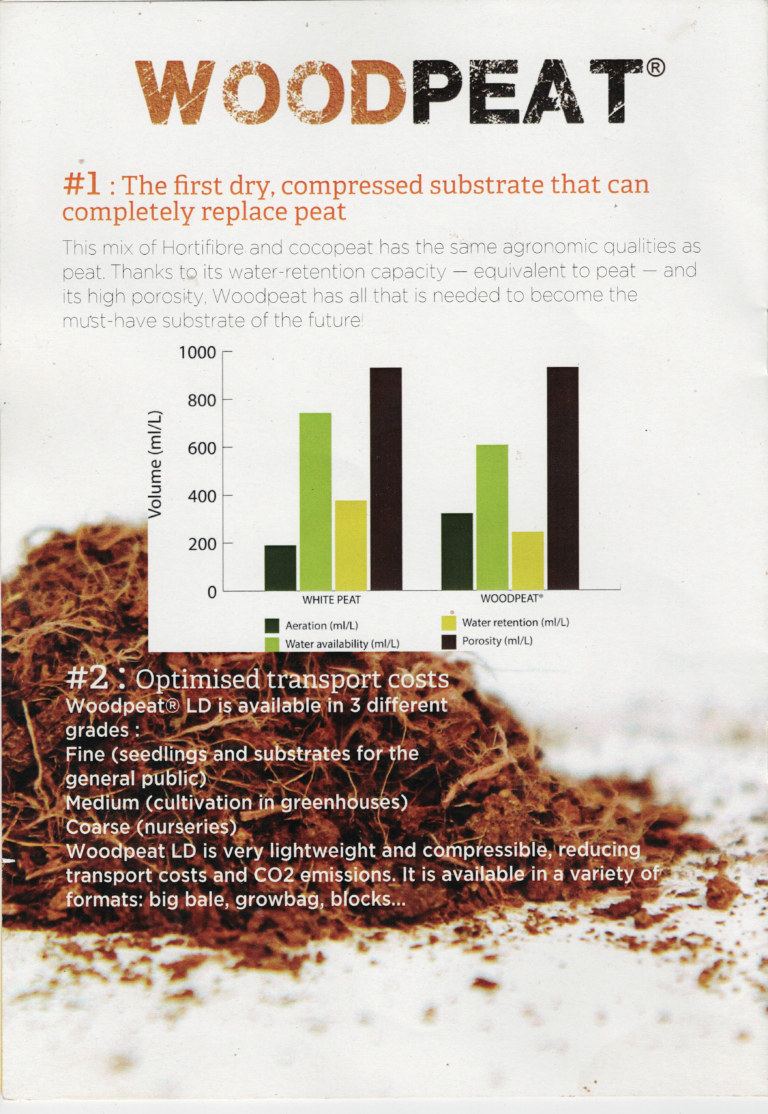

WOODPEAT MIX

COCOPEAT

+ WOOD FIBRE mixed together

In India Wood fibre will be blended with local coco peat and re-exported. The Wood fibre will be mixed with coco peat in order to create a substrate (potting soil).

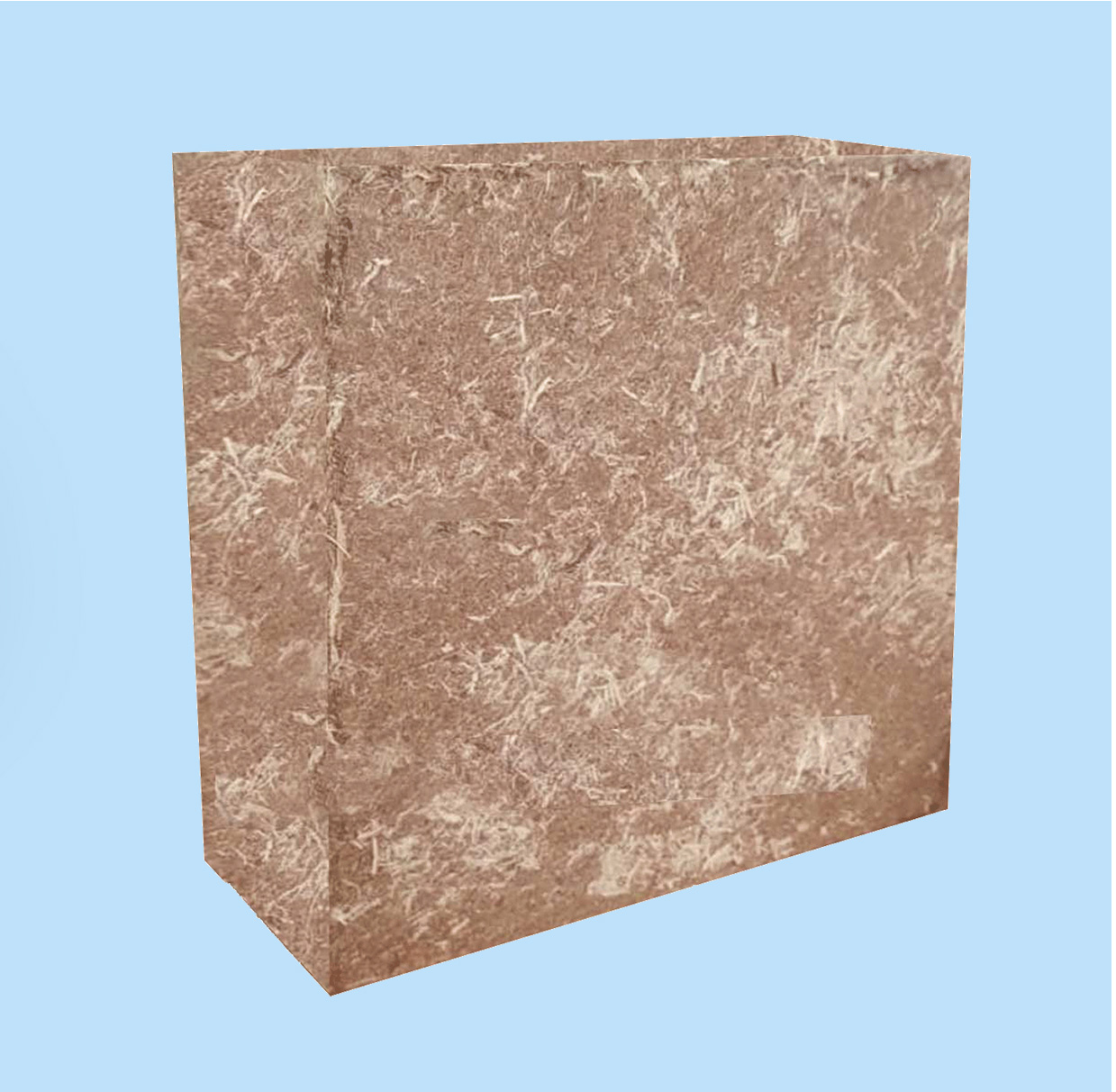

PRESSED WOODPEAT

The powder is compressed into molds using high pressure, forming the compact Woodpeat Block

FINISHED PRODUCT PALLET PACKING

After the production process and packing process completed

the finished goods are exported to various countries like Japan, USA, France,

Korea.

COCOPEAT PRODUCTION PROCESS

Once the husks have been received in our production plant, they are stored centrally for at least six weeks, after which further processing can begin. The husks are beaten or decorticated to remove the fibers, which leaves us with coco peat. The coco peat is transported to our storage bunkers immediately after the fibers have been removed. There it is stored and so begins the ageing process in which the coco peat is stabilized. This process takes at least four months. Once it is over, we sieve the coco peat to remove the last remaining fibers. The coco peat is then dried and taken to the mixing section to mix with wood wool.

WHAT IS WOOD WOOL AND THEIR USES

Wood wool , also known as Wood Mulch or wood Fiber, is a product produced when pine wood chip is extruded to obtain fibers. The process of production is happening at high temperature and pressure, this guarantee that no life is present in the final product, making it stable.

Wood Wool will be used as a first material in substrate (potting soil) it is blended across the world with other raw material in order to obtain a blend that we call substrate (=potting soil),in order to Grow plants.

Finally, Wood wool in the form of 22.5 kg and opened with the help of bale opener and finally loosen wood wool to mix with cocopeat.Wood wool , also known as Wood Mulch or wood Fiber, is a product produced when pine wood chip is extruded to obtain fibers. The process of production is happening at high temperature and pressure, this guarantee that no life is present in the final product, making it stable.

Wood Wool will be used as a first material in substrate (potting soil) it is blended across the world with other raw material in order to obtain a blend that we call substrate (=potting soil),in order to Grow plants.

Finally, Wood wool in the form of 22.5 kg and opened with the help of bale opener and finally loosen wood wool to mix with cocopeat.

PRODUCTION PROCESS OF WOODPEAT

WOODWOOL + COCOPEAT=WOODPEAT

In India Wood wool will be blended with local coco peat and re-exported. The Wood wool will be mixed with coco peat in order to create a substrate (potting soil). Wood wool and coco peat are completely complementary on an agronomical point of view creating a balanced substrate perfect for the cultivation of many plants across the world.